Water For Distilleries

It is a known fact within the distillery society, that each distillery has its own unique specifications giving them their own, unique signature.

These days there are so many options for distillers to improve their production sites and equipment, and experiment with so many ingredients that can add divine and unusual flavours to spirit drinks. All this makes the distillery sector so exciting and diverse.

On the other hand, there is one standard and vital ingredient that many people wouldn’t spend much time thinking about and this is water. Most people think of water as a simple ingredient, but it has so many characteristics that can affect the flavour and appearance of spirit products. To achieve a high-quality final result, distillers target specific water characteristics and consistency throughout the distillery process.

Distillery water treatment

Distillers use purified water to reduce their products in strength after maturation and before bottling.

It is vital to remove the majority of minerals and organics from the water for reduction, to avoid impacting taste and to prevent unwanted reactions and hazes. Most common issues that can occur are:

- Calcium in the water – at this stage leads to calcium oxalate process forming small colourless or white crystals

- Calcium Oxalate isn’t soluble in alcohol or water and is often called “floc”. By using a Reverse Osmosis water filter system to eliminate the Calcium, your master distiller will be able to use perfectly crafted water every single day

- Magnesium ions in the water can cause haze

- Iron in the water used to reduce whisky – can turn its colour black

To avoid any of these issues distillers use pure Reverse Osmosis (RO) and some will also use totally deionised water.

A water purification technology like Reverse Osmosis enables distillers to ensure that they will remove any unwanted minerals and preserve the uniqueness and quality of the final product.

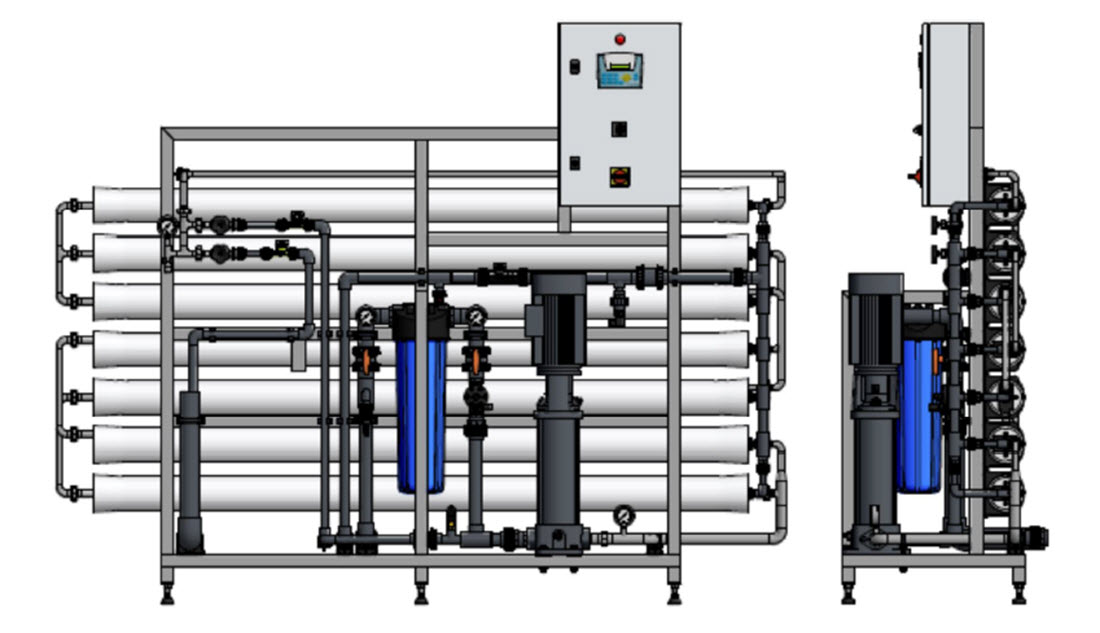

RO systems work by using a pump to push inlet water across a semi-permeable membrane to produce purified water. By applying a back pressure, the water molecules flow through the membrane, leaving up to 99% of dissolved salts and other contaminants on the concentrated side of the membrane, which goes to drain or can be recycled through the inlet to reduce wastewater.

Whisky distilling requires a lot of water. Along with malted barley and yeast, water is one of the three essential ingredients required in the distilling process. No surprise, then, that whisky takes its name from the Gaelic uisge beatha, meaning “lively water” or “water of life”.There are an estimated 108 distilleries licensed to produce Scotch whisky and, according to the Scottish Whisky Association, but this is always changing in the rapidly expanding number of new sites being developed. The industry exported 93 million cases worldwide, generated exports of £4.3 billion and directly employed around 10,000 people, many in economically deprived areas.

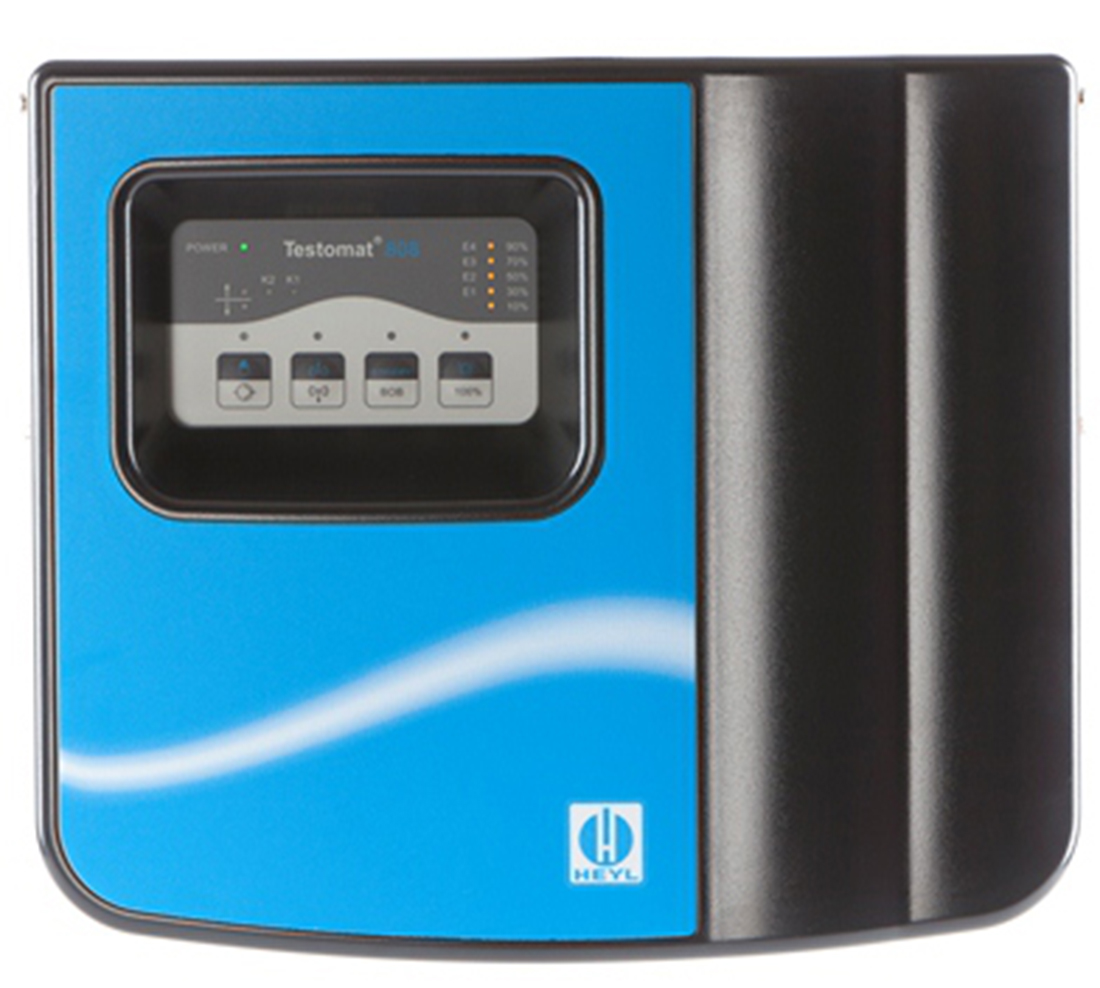

Our filtration systems for distilleries