WATER TREATMENT FOR GLASS CLEANING AND CUTTING

Lubron have years of experience providing quality water systems to supply demineralised water for use in glass washing and cutting operations.

We work with the major suppliers of machinery used for cutting, cleaning and inspection of sheet glass to ensure that your glass is smear and spot free and ready for despatch to your customers.

To reduce water consumption and reduce your carbon foot print we also supply water recycling systems to filter and reprocess the used water from your machinery.

Our solutions for glass cutting and cleaning water treatment

Water Softening

Our range of water softeners remove the Calcium and Magnesium in the water reducing the hardness in the water that causes scale issues when glass dries and also protects your valuable equipment.

This is the minimum level of treatment that we would recommend to ensure the quality of your final product and longevity and reliability of your equipment.

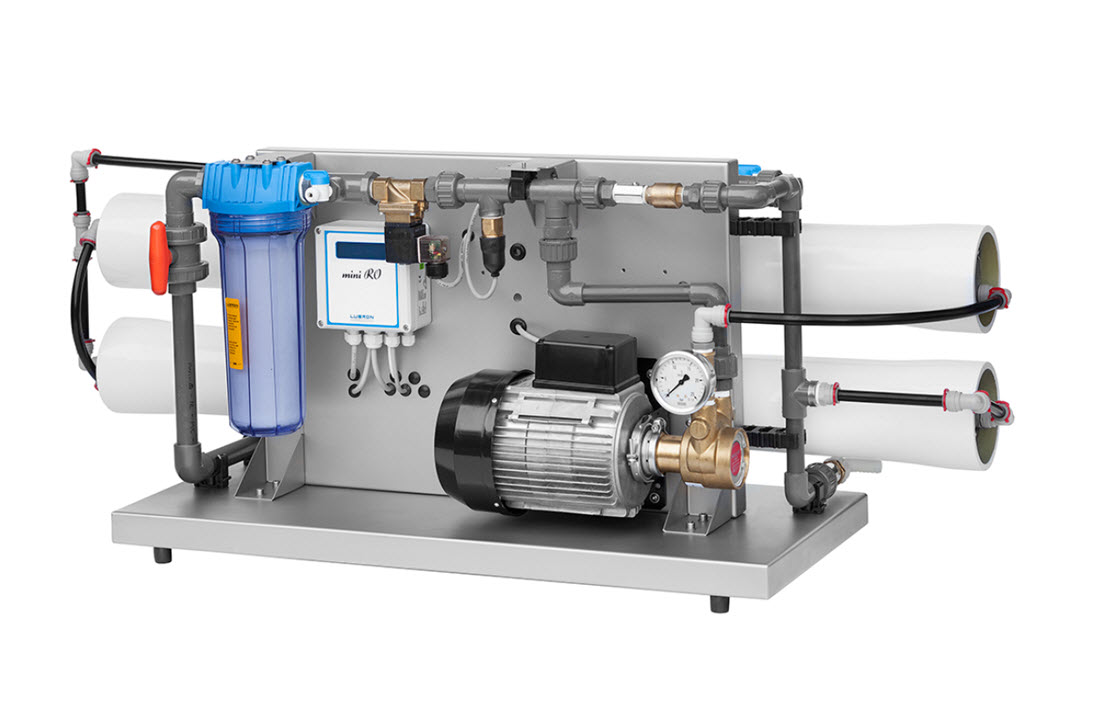

Reverse Osmosis

Reverse Osmosis is a process that uses high pressure and semi-permeable membranes to create demineralised water.

Using this pure water eliminates streaks and smears and ‘water-spotting’ on the glass and prevents damage to your machinery

Water Recycling Systems

We firstly remove the chlorine through a carbon filter, and hardness (Calcium) via a water softener. Then the water passes through a Reverse Osmosis unit which reduces the conductivity of the water to a workable level, say below 20, which is then stored in the permeate tank ready for use. This then supplies water to your washers with a transfer pump. The water is then returned from your washer through a recycle filter to the permeate tank. The recycle filter is automatically self-cleaning, at a convenient time. When the conductivity increases on the return from your washer, the water is automatically diverted to drain, until the conductivity is restored to a pre-determined level.